The origins of the camera enclosure must go back as far as the security industry but it is rather unfair to refer to it as ‘the humble camera housing’.

Cameras have shrunk, resolutions have grown but the rain is still wet and the environment remains hostile to high-tech electronics, so choosing a protection for your camera assembly remains as important today as it was in the earliest days of our industry.

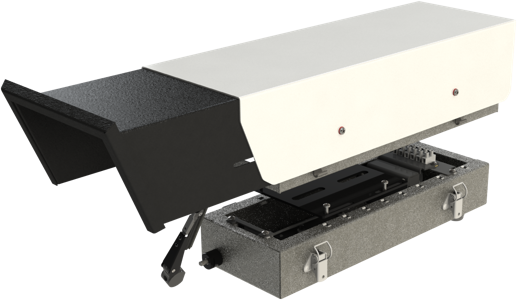

The choice of camera enclosure starts with the size of your camera and lens assembly.

Ensure that your space is optimized but still workable

A common mistake with camera enclosures is choosing the smallest one possible thus making fitting the camera incredibly laborious for the engineer during the installation process. This creates an opportunity for failure as well as increasing the cost of installation due to the extra time taken trying to reach an ill-thought-out screw or connector.

The second most important consideration is the environmental conditions the installation must withstand. Driving rain, direct sunlight, low temperatures, high temperatures and corrosive elements all have to be assessed to ensure the installation is a success and the camera delivers the kind of results the marketing literature boasts it can.

Clean screen = best quality images

ITS’s EH series camera housings come with an integrated self-parking wiper. The wiper is especially useful in areas that have any kind of airborne contaminants such as power plants and transport hubs. It is very easy for a camera image to be compromised with dirt on a screen, even more so if that camera is using auto-focus. The wiper can easily be activated using an optional module that connects directly to the camera alarm output (analogue or IP).

Available in two formats, standard and 316 stainless steel, the EH series camera housings can withstand the worst of environmental challenges and ensure the camera installation delivers the quality images it was designed and chosen for.

Make the installation your installation

ITS Products offers a unique design and build customisation service. For clients with specific installation challenges, a unique build configuration may enhance performance or reduce engineering cost. We work with our customers during the design phase, providing engineering materials for customer submissions, manuals and handover documentation. Why choose good enough when you can have an exact solution?